The complete HVAC package

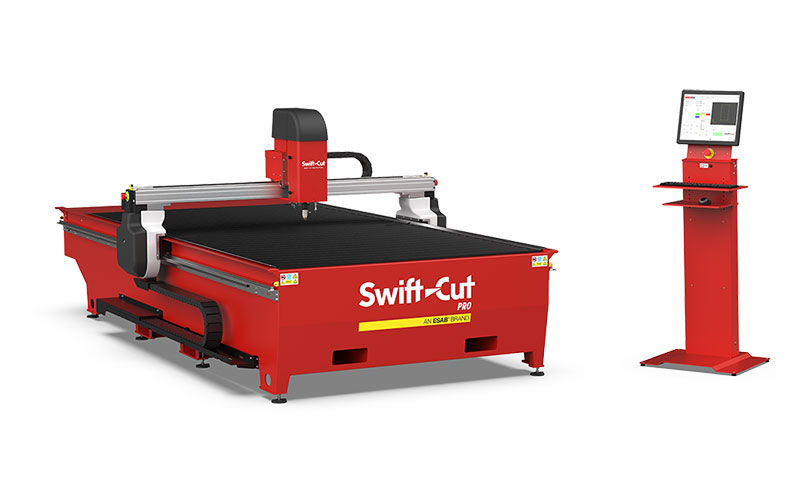

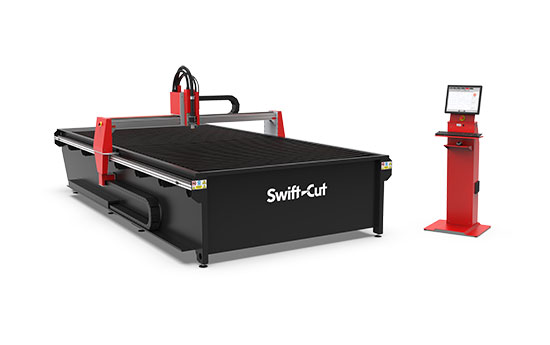

Taking the exceptional engineering of our bestselling Pro Series, adding in some of the world’s most recognisable ducting software from the likes of Trimble, PractiCAM and CAMduct, alongside a class leading Hypertherm or ESAB plasma system, and an efficient yet powerful fume extraction and filtration unit, provides you with a high performance, reliable, sheet metal plasma cutting solution like no other

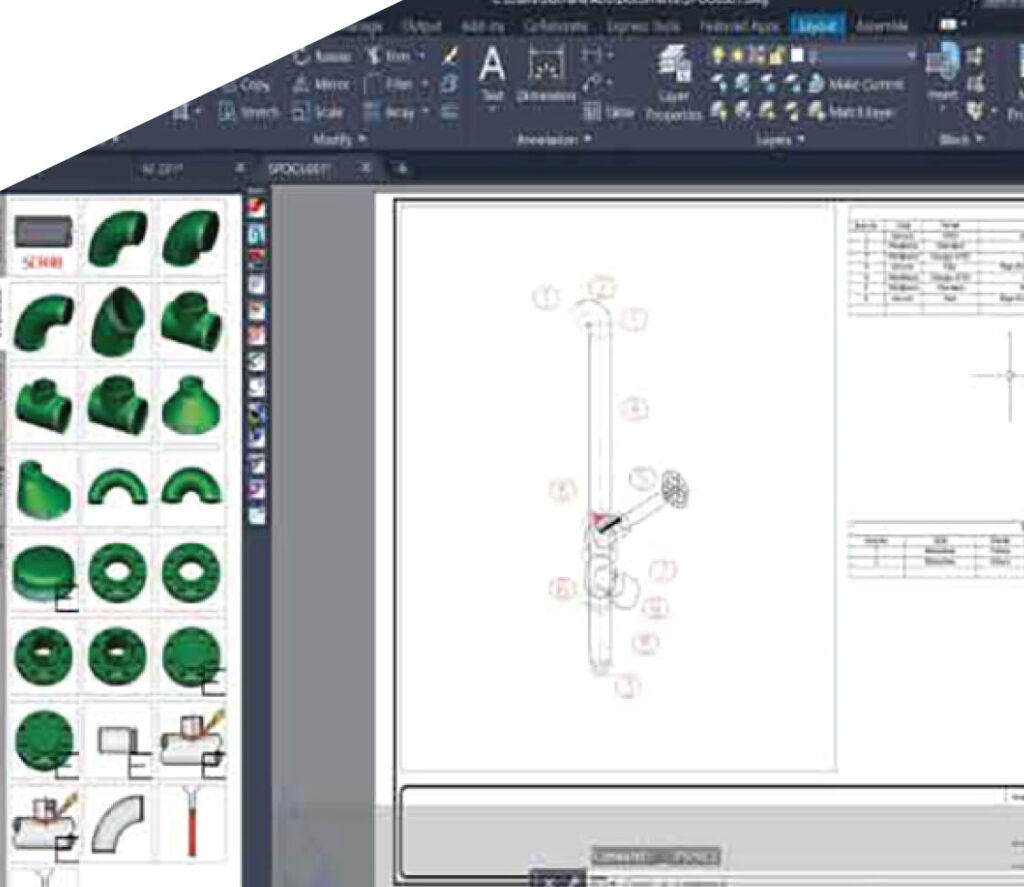

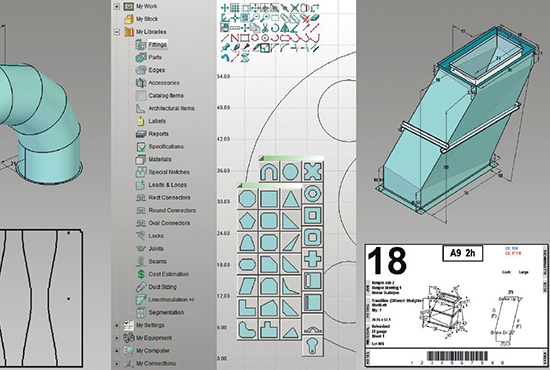

The largest fitting libraries

Choose between Trimble, PractiCAM and CAMduct which have the largest fitting libraries of any other HVAC software in the world. Practically all rectangular, circular, and flat-oval ductwork components along with a vast array of standard components can be created and altered to your specific dimensions in seconds. Add to this advanced nesting capabilities for full sheet material ultistaion, and powerful reporting, tracking and management report generation, and it’s easy to see why your search for HAVC software stops here

No limitations

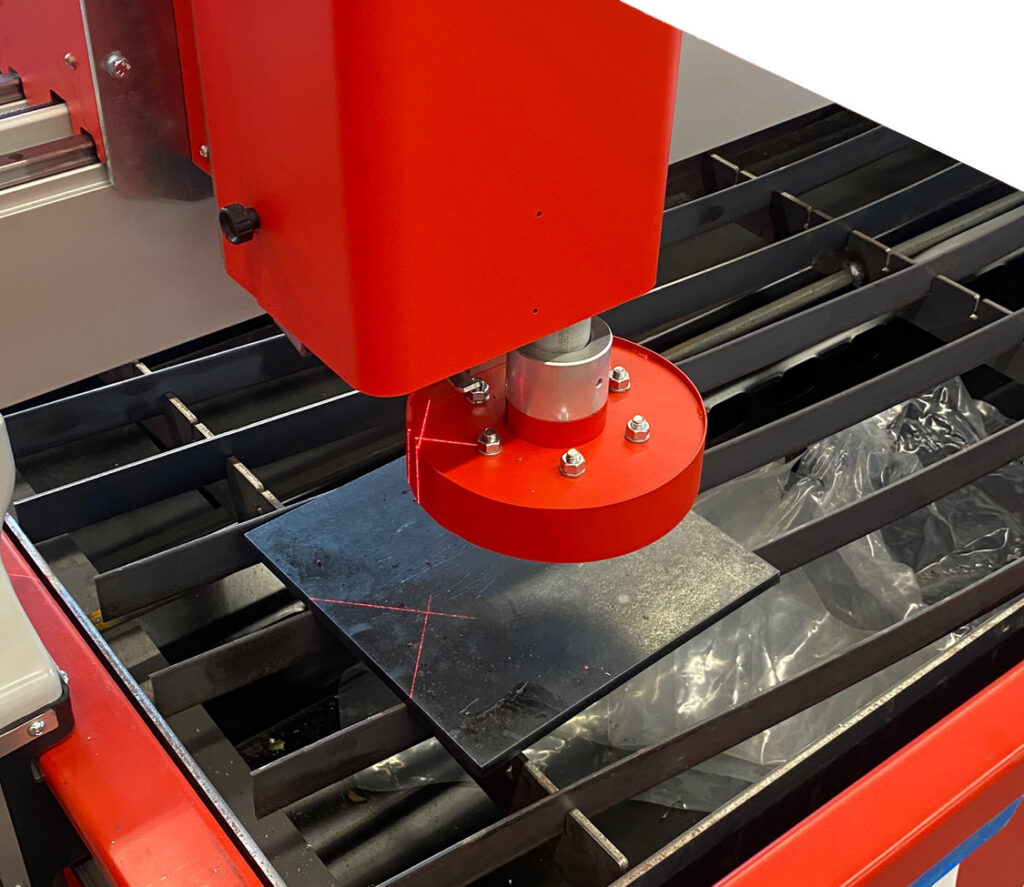

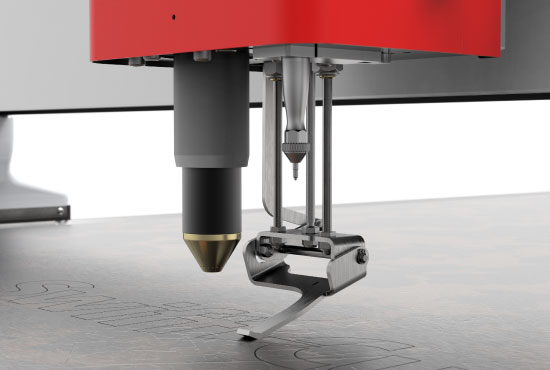

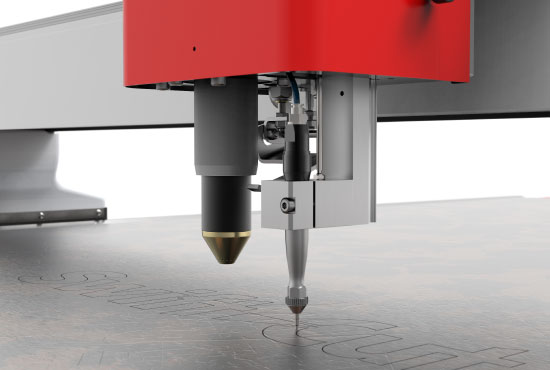

The first HVAC-dedicated CNC plasma system that can switch over to 1” steel plate cutting in minutes! Benefit from the best of both worlds with a quick-change plate rider that ensures even the thinnest sheets remain flat for that perfect cut. Then when you need to, switch to full cutting capacity and benefit from Digital Torch Height Control (DTHC), voltage sampling, and unparalleled cut quality and extended consumable life.

Complete Package

Swift-Cut HVAC Pro plasma table with Hypertherm or ESAB plasma system, filtration extraction unit and all software included as standard

Benefits of the HVAC Pro

There’s lots of reasons why you should consider the Swift-Cut HVAC Pro as your next investment. Here we’ve summarised the top 10!

- Full online support worldwide

- Soft sense initial height sense system for accurate plate referencing even on sheet as thin as 0.5mm. Reduce annoying torch misfires and material collisions with highly accurate Z axis referencing

- Autodesk CAMduct Fabrication. Market leading HVAC fabrication software for automating the design and nesting of your ductwork components. CAMduct offers a large library of parametric shapes commonly used in the HVAC ductwork fabrication sector. Along with comprehensive reporting tools to help minimise down time with your fabrication workflow

- Complete serial link control of the plasma power source ensures the correct cutting amps are selected every time by the software on the operators console

- ITHC – our highly responsive digital torch height control will automatically follow any changes of the material height commonly found when cutting thin material without damaging or scratching the plate

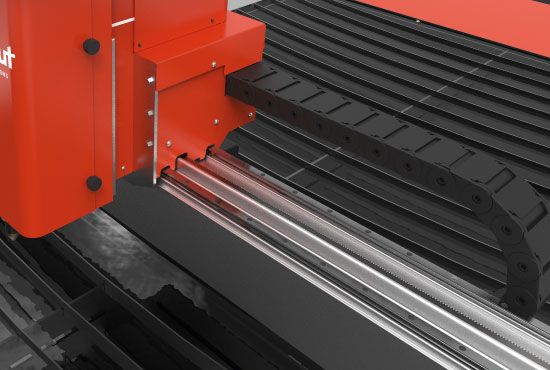

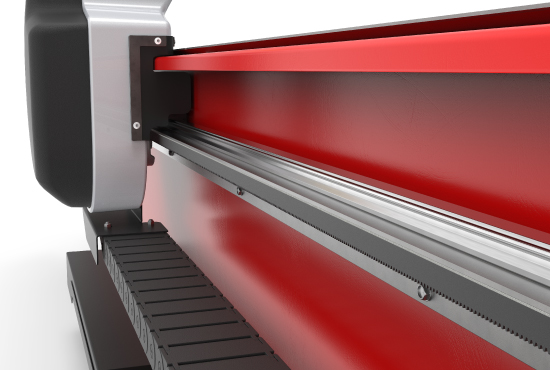

- Linear rail and rack and pinion drive system to enable high cut speeds and accurate change in cut direction

- 6-zone downdraft base design enables you to focus the extraction exhaust directly beneath the cutting torch for maximum efficiency. This reduces the extraction fan specification required, which in turn keeps noise levels to a minimum

- 3000mm x 1500mm cutting area in a compact footprint can handle all standard sheet sizes with ease

- Enjoy cut speeds of up to 9m/min, meaning increased output over other HVAC systems

- Extraction fan or filtered extraction system options available

We have outstanding feedback

We have outstanding feedback

“We have been totally blown away with the machine and it has exceeded all our expectations”

Andy Groves Profab

“Swift-Cut are a great team to work with”

Charl Botha Brits Plasma Cutting

Take control of your cutting with a Swift-Cut CNC machine

Whether you’re ready to buy, would like a demonstration in our customer experience centre, or just have some questions regarding our machines or software, please feel free to leave an enquiry and one of our team will be in touch.

- Ease to use & Affordable

- Heavy duty design & Proven reliability

- Fantastic support

- Superb cut quality

- Quick setup & Feature rich

Technical specification

Heavy duty gantry and base

Heavy duty gantry end castings with machined faces, together with the lightweight but rigid gantry, and fully welded base, provides a precise and stable platform for the cutting head. It’s compact too with one of the smallest footprints in the industry

Full software suite included

Choose from Trimble, PractiCAM and CAMduct to provide the perfect software solution for your business. Vast duct fitting libraries, cost-saving tools, and management reporting are all available form these three market leaders

Intelligent torch height control and soft sense

ITHC and Soft Sense initial hight sense ensure the perfect pierce and cut height no matter what thickness of material being cut. And with no plate rider and increased gantry clearance, you can use the machine for thicker materials too

Engraving head

The SwiftMARK engraving tool allows you to mark and cut in one operation, meaning no more outsourcing or moving project from one machine to another. Included as standard

Precision linear rail

Linear rail on all axes, including twin rail on the x-axis, ensures straight, accurate, and repeatable movements, plus a smoother motion compared to other guide systems

Operators console

Ergonomic operators console with touch screen and keyboard/mouse inputs. The console can be placed on either side of the machine

All technical information and more is now available in our brochures.

To get access to all of our documentation you will need to complete this form….

Powermax65 SYNC™ – Cut up to 5/8″

Powermax85 SYNC™ – Cut up to 3/4″

Powermax105 SYNC™ – Cut up to 7/8″

ESAB A120 – Cut up to ¾”

Swift-Cut is the world’s first light industrial CNC OEM to fully test and integrate the new Hypertherm Powermax SYNC™ plasma systems with our cutting machines and software…

Our tech specs are now available in our brochures.

Please complete this short form to gain full access

See other Swift-Cut products

See other Swift-Cut Products

FAQ's

FAQ’s

Plate riders touch the material when cutting. If there’s anything in the way, they can get caught. If a part lifts, it can knock the torch head out of line. With the HVAC Pro from Swift-Cut, we use Intelligent Torch Height Control (ITHC) combined with our soft-sense initial height sense system to provide highly accurate plate referencing and cutting even on sheet as thin as 0.5mm

We’ve tuned the HVAC Pro to provide the optimum cut speed and edge finish when combined with the Hypertherm Powermax 45XP, and HyAmp torch technology. This combination of versatility and robustness allows for moderately intensive use in all environments, whilst still maintaining fantastic value for money and low running costs

Not at all. All Swift-Cut software is subscription free for the life of the product and we are one of just a few Autodesk partners in the world who can offer CAMduct software as a standalone licence with no monthly fees

Yes you can. The benefit of the HVAC Pros design is that with a high gantry and no plate rider, it’s easy to switch from 0.5mm to 10mm sheet with just a few clicks of the mouse. The software is programmed to run at the optimum speed and cut height for all material thicknesses, so you don’t have to worry. It’s as easy as 1,2 3!