affordable, quality

waterjet cutting

affordable, quality

waterjet cutting

It cuts virtually anything!

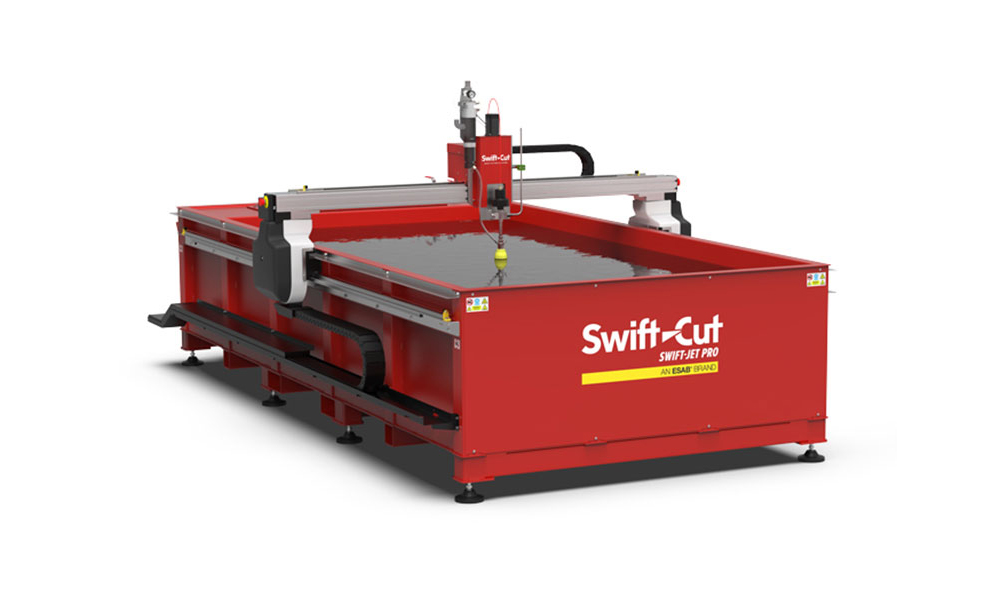

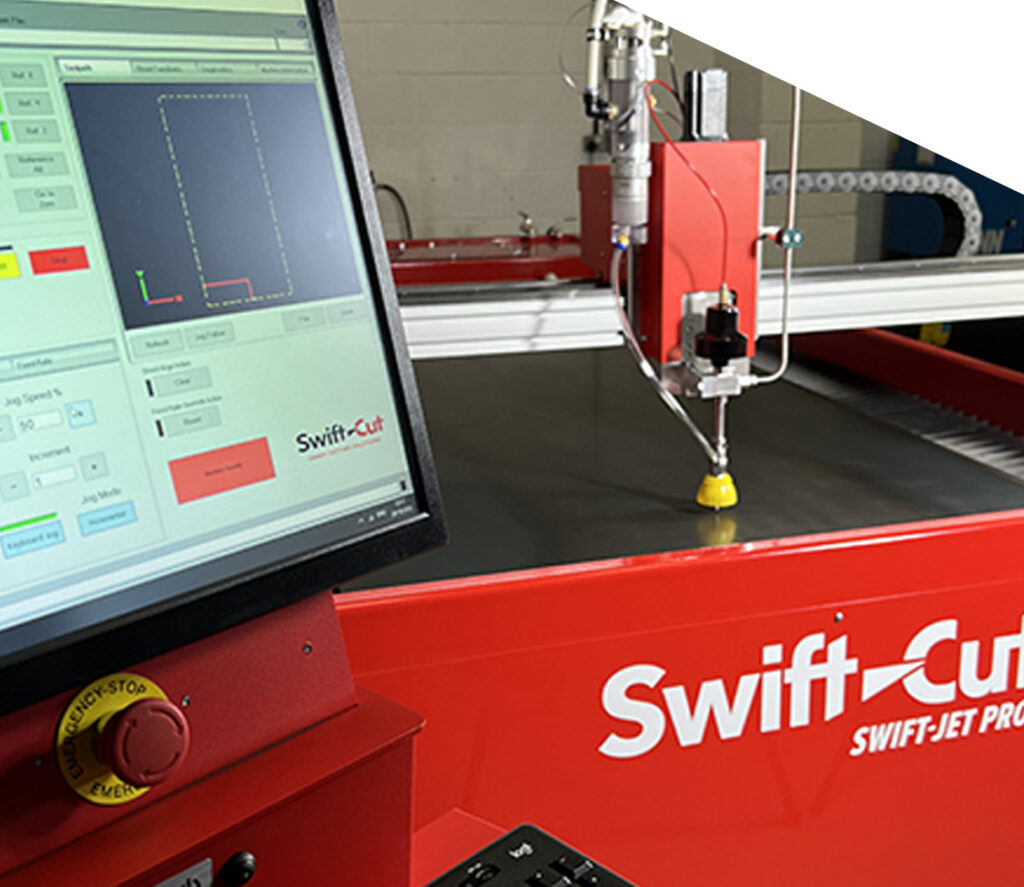

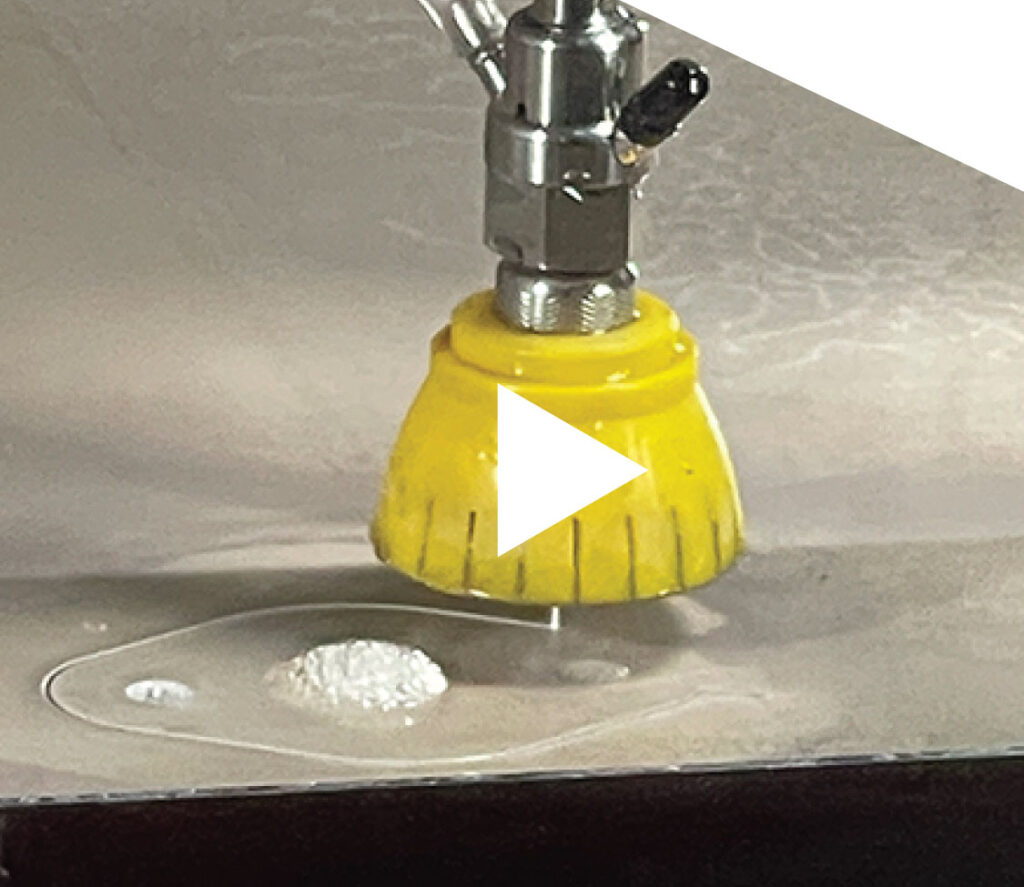

The Swift-Jet Pro is one of the most versatile CNC cutting machines available today. From glass to granite, rubber to resin, and steel to stone, this machine cuts through it all. Using a combination of highly pressurised water, mixed with abrasive (garnet), the resulting focused beam of water makes light work of even the toughest materials. Smooth edge finish, no heat affected zone and little to no post processing.

Affordable, smart cutting

Undisputedly Swift-Cut, the Swift-Jet Pro is bringing the incredible capabilities of waterjet cutting to the masses – a table that has combined high-quality software with our robust, precision engineered table build, and made it affordable. Coupled together with an energy efficient, long service life, high pressure pump, ensures lower running costs and a faster ROI compared to other waterjet systems.

See it in action

“Nothing else comes close in terms of price, features, and support”.

We have dedicated experience centers in many locations around the world. We can also carry out personalised remote demonstrations over Zoom, TeamViewer, Microsoft Teams and WhatsApp platforms. You can send-in or bring parts or drawings with you to cut out, or we can create something for you which best represents your particular application.

We have dedicated experience centers in many locations around the world. We can also carry out personalised remote demonstrations over Zoom, TeamViewer, Microsoft Teams and WhatsApp platforms. You can send-in or bring parts or drawings with you to cut out, or we can create something for you which best represents your particular application.

Benefits of a Swift-Jet Pro

There’s lots of reasons why you should consider the Swift-Jet Pro for your next CNC waterjet cutting machine. Here, we’ve summarised the top 12!

- Full online support worldwide

- Cut metal up to 50mm thick and low density materials up to 100mm thick

- End the reliance on your suppliers for cut parts

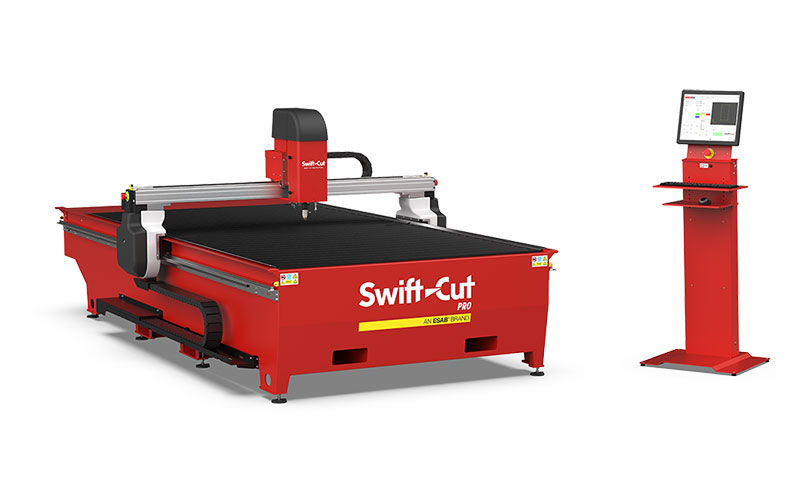

- Standalone operators console

- Cut virtually any material!

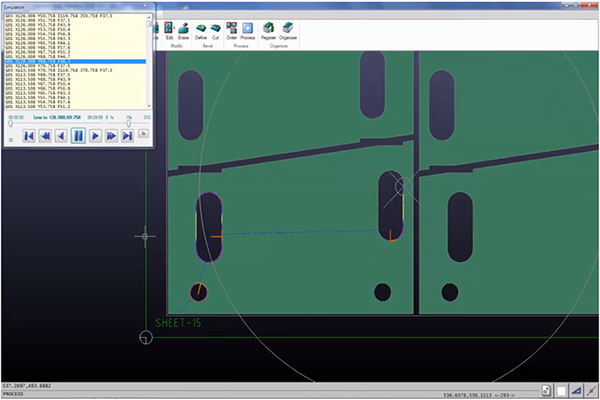

- IGEMS software included as standard

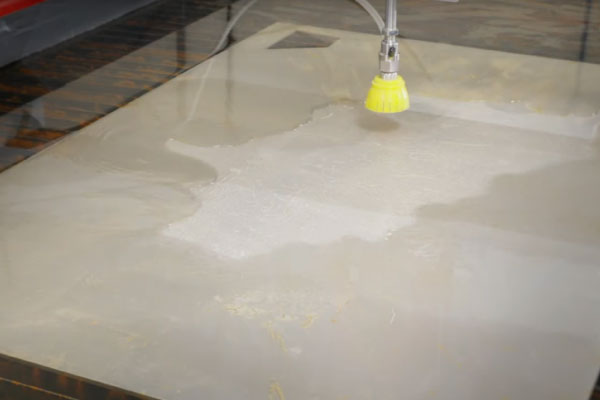

- Underwater cutting system

-

High/low pressure cutting

- Lower running costs

- Triple sealed linear bearings

- Fully welded base

- Lower running costs than intensifier pumps

- Full online support worldwide

- Cut metal up to 50mm thick and low density materials up to 100mm thick

- End the reliance on your suppliers for cut parts

- Standalone operators console

- Cut virtually any material!

- IGEMS software included as standard

- Underwater cutting system

- High/low pressure cutting

- Lower running costs

- Triple sealed linear bearings

- Fully welded base

- Lower running costs than intensifier pumps

We have outstanding feedback

We have outstanding feedback

“Nothing else comes close in terms of price, features, and support”

Charlie Insley Burton Rubber

“We’re astounded that such impressive engineering is still so cheap”

Michael Palmer CDC Designs

Take control of your cutting with a Swift-Cut CNC machine

Whether you’re ready to buy, would like a demonstration in our customer experience centre, or just have some questions regarding our machines or software, please feel free to leave an enquiry and one of our team will be in touch.

- Ease to use & Affordable

- Heavy duty design & Proven reliability

- Fantastic support

- Superb cut quality

- Quick setup & Feature rich

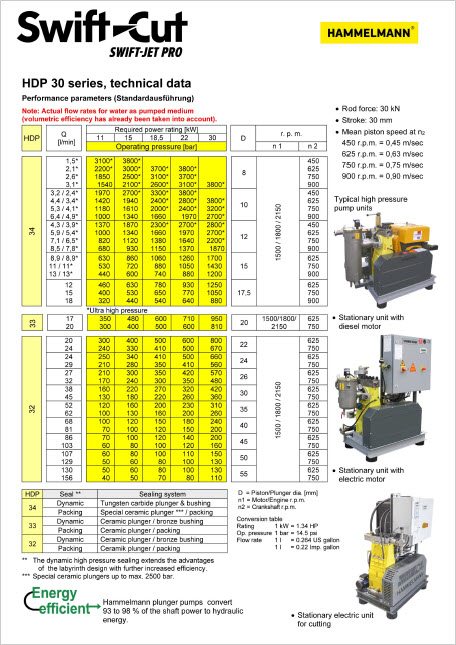

Technical specification

Hammelmann direct drive pump

The quality of the German designed and built Hammelmann high pressure pump is indisputable. 30% more energy efficient than other waterjet systems, and much longer service intervals to match

IGEMS and SwiftCNC

Market leading software combined to produce the perfect partnership for powerful waterjet programming control

Submerse your cutting material with ease which means less noise and less mess. Water level can be raised and lowered by up to 60mm

Heavy duty base

Fully welded base provides support and rigidity to the cutting bed ensuring the maximum levels of accuracy remain

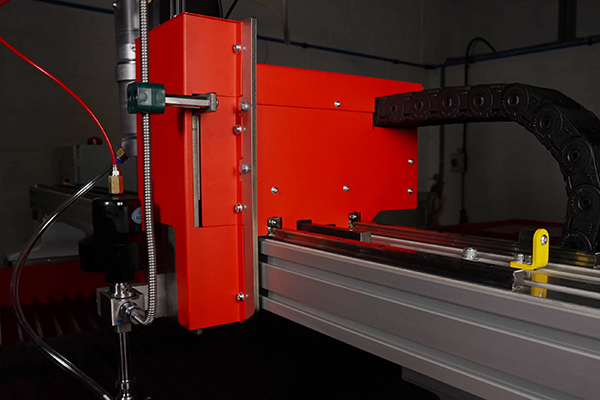

Sealed linear bearings

Triple sealed linear bearings with scrapers on X and Y axis protect against moisture and cutting particulate ingress

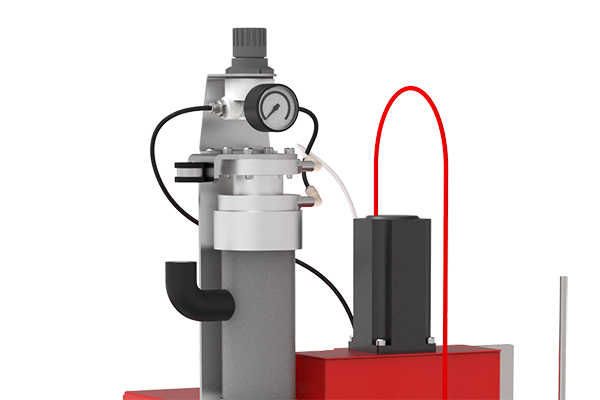

Abrasive regulator

A mini hopper with abrasive metering system regulates the flow of garnet into the nozzle, improving flow consistency and reducing the likelihood of blockages caused by surges and fluctuations in the garnet feed

All technical information and more is now available in our brochures.

To get access to all of our documentation you will need to complete this form.

Our tech specs are now available in our brochures.

Please complete this short form to gain full access

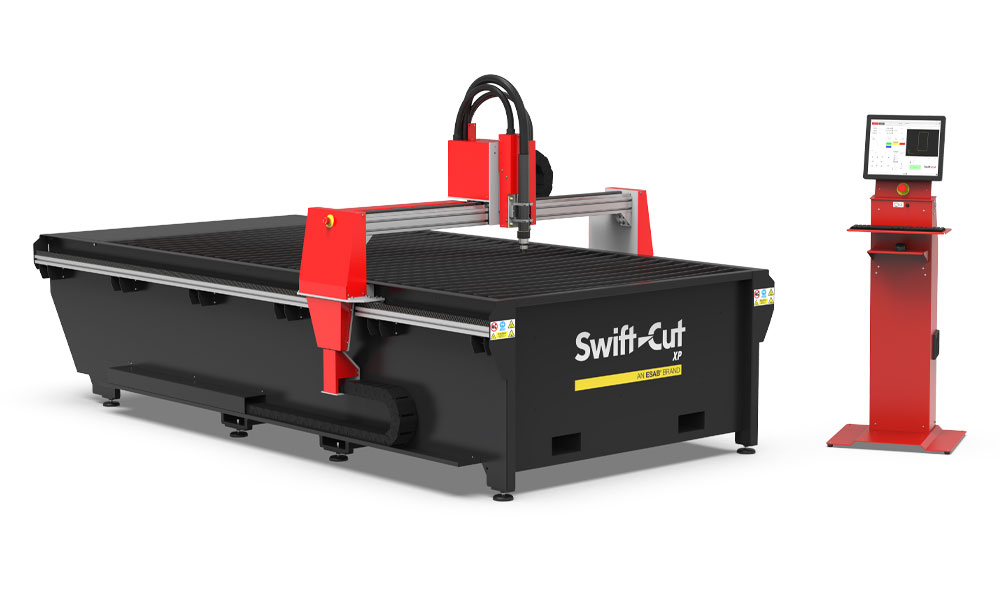

See other Swift-Cut Products

FAQ's

FAQ’s

The Swift-Jet Pro is designed to cut a wide variety of materials. From expanded foam for packaging materials, to granite slabs for kitchen worktops, our machine can cut them all. The only materials you cannot cut are tempered glass, diamonds and brittle plastics

Our Swift-Jet Pro waterjet requires an electricity supply, a water supply and a compressed air supply in order to run. The table (inc. console) requires a single phase 110v-230v (6A-4A) electricity supply. The Hammelmann high pressure pump requires a three phase 380v-480v (40A-30A) electricity supply, and standard tap pressure water supply. The compressed air supply will need to be clean and free of moisture, oil, and any other contaminants. The compressor will need to deliver 17CFM of air flow and have a holding pressure of 110psi

Like all cutting processes, speed is determined by the type and thickness of material being cut, the power of the machine, and the quality of cut required. The Swift-Jet Pro machine can cut at speeds up to 10m/min for soft materials like foam, however 25mm thick granite will cut at 20mm/min

Abrasive cutting basically means cutting with a mixture of water and abrasive garnet material. The garnet is what allows the high-pressure water stream to cut through dense materials and it is introduced into the water stream just above the cutting nozzle before being directed down onto the sheet material. The garnet is readily available and is classed as a consumable item so once it’s been used to cut through your material, it enters the water tank where it settles to the bottom and will have to be manually removed once it reaches a certain level