Glanville Metal Spinning

[vc_row][vc_column][vc_empty_space height=”60px”][vc_column_text]

Glanville Metal Spinning has a large plant in Croydon, Surrey where they focus on metal spinning.

What is metal spinning, you ask? True to its name, metal spinning is the craft of taking a sheet of metal and spinning it at a very high speed against a pressurised block. This spinning then shapes the metal into a axially symmetrical shape. Urns, vases and platter lids are all examples of metal spinning products. Lights are also popular products and at Glanville Metal Spinning, they produce a lot of lights! Their fixtures, which Glanville is commissioned to produce for a range of commercial clients, vary in size and shape but they’re all skilfully produced in their workshop.

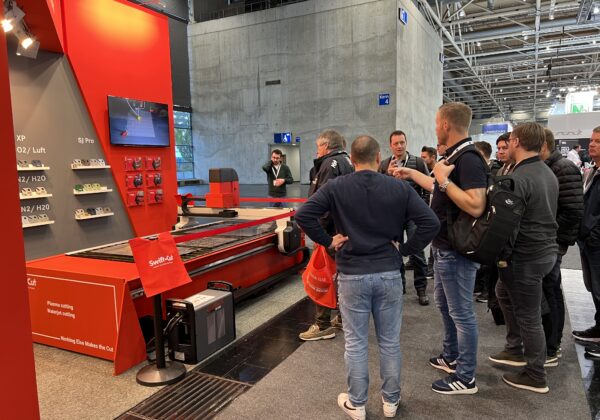

Since purchasing their Swift-Cut CNC Plasma Cutting Machine, Glanville’s been able to change the way they produce their products. How? For one, it allows them to save time and money as they’re now able to cut their own base products– everything from flat metal disks to brackets– and make them the exact size and shape they need. Without having to rely on a third party, the Glanville team can be more industrious and innovative, which has allowed them to increase their client offerings.

We can now use the plasma cutting table to create our own in-house tools to assist use the complex formations we create.

With the increase in their production, the Glanville team reckons the machine will pay for itself within its first year. And after that? “Well, we’re already thinking about purchasing another one!”

[/vc_column_text][/vc_column][/vc_row]